ACCESS OIL & GAS RESERVES BY DRILLING CHEAPER

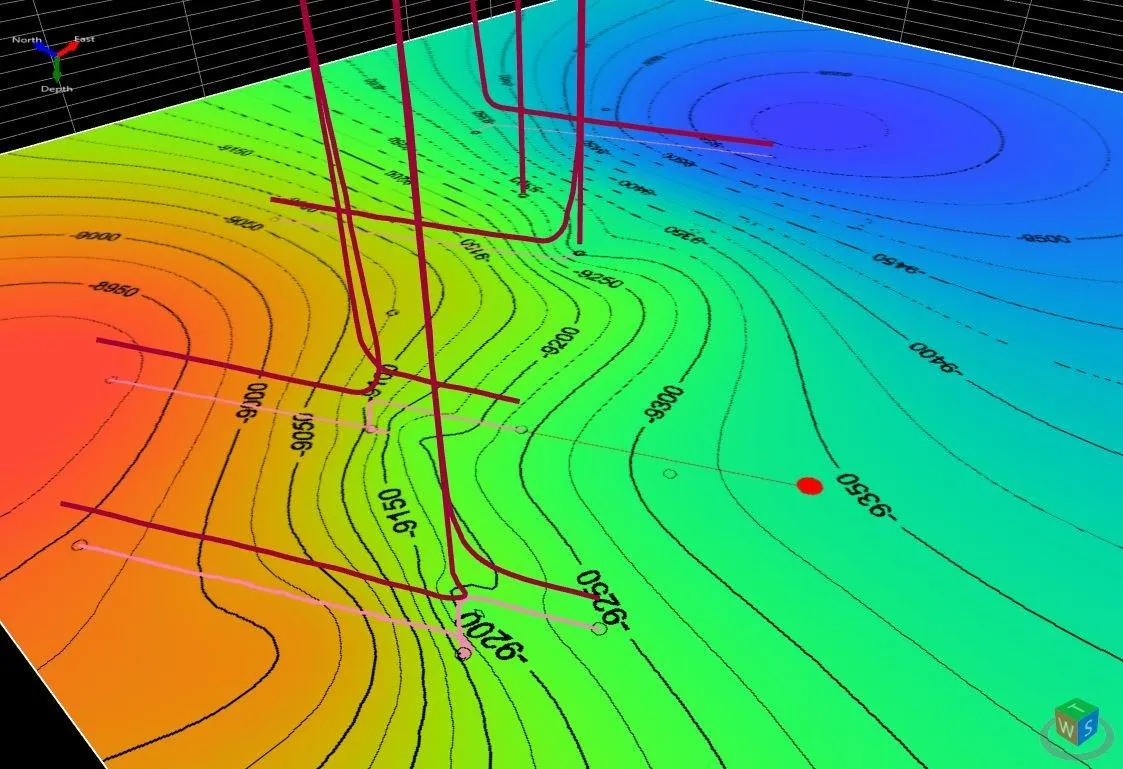

Black Belt Short Radius Drilling, LLC has extensive short radius drilling project management experience that strategically targets enhancing production volumes by repurposing existing wellbores to access known reserves. Decrease capital expenditures, reduce new drill risk, and leverage existing infrastructure to optimize resource extraction and significantly extend the productive life of oil fields to increase the overall economic return from established reservoirs.

PROSPECT EVALUATION

Increase project success with closely managed geologists and reservoir engineers for prospect evaluation.

PROJECT MANAGEMENT

Deploy our experience in Vendor Qualification, Management, and Performance to increase success.

WELLWORK EXECUTION

Managing projects for well work and drilling operations with expertise and precision.

WHAT ARE THE PROBABLE RISKS?

Staffing Resource Deficiency

Lack of in-house staff to focus on learning the skills for a niche project.

Skill Shortage

Untrained Drilling Engineers, Rig Crews, Vendors, and Directional Drillers.

Geological Variability Analysis

Slim hole steering issues, Oil/Water Contact, faulting, and landing on target.

Casing Exit Strategy

Pivotal decision considering cement, casing position, and well construction.

Structural Integrity Assessment

Options for final well design with wellhead strategy, casing, liner, or open hole.

Advanced Motor Procurement

Sourcing of slim hole high dogleg mud motors and qualified local rebuilding.

Vendor Qualification Gap

Vendors must know the exact expectations to be able to perform in a unique operation.

Rig Equipment Determination

Selecting the wrong drilling equipment will negatively impact your operations and result in substantial downtime.

MITIGATIONS TO IMPLEMENT

PROJECT COORDINATION

A minimum of 2 planning hours to 1 execution hour is required for success when things go wrong.

DIRECTIONAL PROCUREMENT

Qualify your directional vendor's Directional Drillers, equipment availability and BHA design.

WORKSTRING SELECTION

Deploy engineering and real world principles to mitigate buckling, corrosion, stress, and fishing.

LOGGING

OPTIONS

Understand Lost In Hole and Lack of Information with logging tools.

ABOUT BLACK BELT SHORT RADIUS DRILLING, LLC

Short radius drilling practices have been available to the oil and gas industry for decades yet used very sparingly. Only one field, the Yates Field, has seen the continuous use of short radius drilling practices for decades. Due to the inherent risks of entering old wells, exiting the casing, landing on TVD, and drilling sufficient lateral length, mistakes are costly and almost always lead to budget overruns. With a whole generation of engineers, field staff, and vendors now solely trained on shale play wellwork, conventional wellwork knowledge is extremely rare.

Seeing the desire for the United States oil and gas industry to remain economically competitive on the global stage, Black Belt Short Radius Drilling, LLC was created to offer these services to operators that realize the potential production of the thousands of undrained acres on their vertically drilled leases. With experience gained by the continuous engineering and managing the drilling of hundreds of short radius horizontal wells, the Black Belt Short Radius Drilling, LLC team can be deployed to access your opportunity.

"Black Belt Short Radius Drilling targets higher production by repurposing wellbores to access untapped reserves."

FAQ's

Why do I need help drilling a short radius horizontal well?

Everyone has their skills. Even though all of the tools to build a house are sold at Home Depot it is best to hire experts who specialize in the subject matter, stay up to date, and most importantly know what to do when things go wrong.

What logging options are available for a short radius horizontal well?

Total gamma is available. Resistivity, sonic, neutron porosity, density, and other petrophysical measurement tool availability is very limited, and Lost In Hole risk needs to be seriously considered before deploying tools through casing exits and short radius curves.

What type of rig would I use to drill a short radius horizontal well?

Rig selection begins with the hoisting capacity of the heaviest load; usually the production casing string. Slim hole workstring loads are handled every day by workover rigs depending on depth of the well. Then the other mechanical specifications are considered such as derrick height, floor height, BOP requirements, mud system capacity, rotary system, etc. Unlike drilling contractors, workover rigs are a la carte requiring the understanding of drilling equipment, managing multiple vendors, and the need for a strong project manager to bring it all together before vendors arrive on location.

Short radius horizontal drilling has been around a long time. Why has it not become more popular?

Markets develop from the flow of demand and in the upstream drilling market the vast majority of capital spend for the past two decades has been concentrated with new drill, large bore horizontals in shale plays.

Why choose Black Belt Short Radius Drilling, LLC and not another vendor such as a consulting firm or another company that claims they can do this?

As with any operation, vendor qualification is essential for success. Some vendors base their service around their in-house tools and other vendors may have contributed a service to a short radius drilling operation at one time in the past. The skills learned of being responsible for the success of the entire project is only found at the operator level. Our Project Managers understand the roles and responsibilities of each vendor to give you the best chance of success without being forced to use in-house tools.

What makes a great short radius horizontal well candidate?

Cost drivers for short radius horizontal well candidates are not limited to depth, production casing size, wellhead configuration, surface location limitations, production volume requirements, corrosive downhole environmental, pressure, regulatory environment, and vendor capabilities and availability. Having options from multiple wells to reach the desired acreage is highly recommended.

Does Black Belt Short Radius Drilling, LLC participate in the funding of the well?

No. We wish to deliver unbiased client focused decisions. We can create an engineering report for your investor presentation.

What if there is a mechanical issue while preparing the well?

Re-entering an aged well has inherent risks. Our team will aid in a strategy that will search for options to ensure the theory of accessing the reserves is able to be tested to avoid a large capital expenditure loss.

What production casing size allows the highest chances of success?

Production casing larger than 4.5" increases the chance of a successful casing exit, landing on TVD, drilling a horizontal wellbore, and installing casing/liner if needed.

What does it cost to drill a short radius well?

A fraction of the cost compared to a new drill horizontal that can cost several million dollars. A short radius horizontal utilizes an existing wellbore that is no longer economically producing oil and gas and is being considering to be plugged and abandoned.